1. Tuned mass damper (TMD)

Tuned mass dampers, also known as dynamic absorbers, are a type of passive control measure for structures, mainly used for wind resistance and improving human comfort.

By adding an auxiliary mechanism to the main structure, when the main structure is subjected to external dynamic forces, it provides a force with almost equal frequency and opposite direction to the direction of structural motion to counteract some of the structural responses caused by intense external forces.

Its working principle is similar to that of electromagnetic wave in the process of transmitting and receiving. Wind load or pedestrian load acts on the main structure and generates mechanical wave in the main structure, which is called the main wave. The mechanical wave generated by the damper in the mechanism is called the signal wave. The signal wave propagates in the main wave, which is similar to that of electromagnetic wave tuning in the main wave. This is the origin of "tuning" in the name of the damper.

The damping force on the structure includes inertial force, hence the name: tuned mass damper.

The purpose of installing TMD is to resist wind and improve human comfort.

2. TMD product introduction

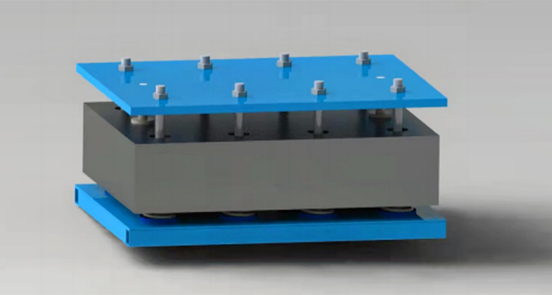

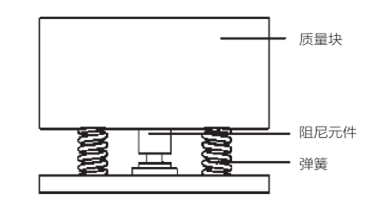

The tuned mass damper system consists of mass blocks, springs, and damping elements. It adjusts the vibration frequency of the damper system itself to the vicinity of the main frequency of structural vibration. Through the interaction between TMD and the main structure, it generates forces that are consistent with the main structure's motion frequency but opposite in phase, achieving the goal of reducing the main structure's vibration.

Tuned mass damper

In theory, there exists the optimal TMD configuration parameters. The larger the additional mass of TMD, the better the vibration reduction effect, but it is often limited by the structural bearing capacity and cost. When ignoring the damping of the main system (usually very small), the optimal parameters for an additional TMD system are:

![]()

![]()

式中:![]() 为TMD系统最优阻尼比,

为TMD系统最优阻尼比,![]() 为TMD质量的主体结构质量之比;

为TMD质量的主体结构质量之比;![]() 为系统最优固有频率,

为系统最优固有频率,![]() 为主体结构频率。

为主体结构频率。

3. Scope of application of TMD

(1) Tall, slender, and open stepped structures (bridges, bridge tower doors, chimneys, television towers, etc.) that are prone to dangerous wind excitations in their own modes;

(2) Pedestrians walking and jumping on large-span floors, floors, stairs, audience seats, and pedestrian overpasses. This kind of vibration is not harmful to the structure itself, but it can cause discomfort to people;

(3) The floor slab of a steel structure processing plant excited by the natural frequency of machinery such as centrifuges and fans;

(4) A ship excited by the natural frequency of an engine or transmission.

4. Key points of production assembly

(1) The quality of the quality block should be reasonably controlled and there should be no significant deviation;

(2) The material of the quality block should be uniform, with a high degree of alignment between the center of mass and the center of mass;

(3) The stiffness error of the spring should not be large, and the deformation between the springs should be coordinated; Conduct tension and compression tests in advance to optimize springs;

(4) The spring must follow the guide rod, which has a low friction coefficient and is coated with lubricating oil;

(5) Space should be left for adjusting the length of the screw to facilitate quality adjustment.

5. Factory documents

(1) Weigh the stiffness of the mass block and generate a weighing report;

(2) Spring stiffness test, generate a spring stiffness test report;

(3) Performance testing of dampers, forming a damper testing report;

(4) TMD natural frequency test, generate a natural frequency test report.

6. Project acceptance materials

(1) Factory certificate of conformity;

(2) Material report;

(3) Factory test report (mass block weighing, spring stiffness testing, damper performance testing);

(4) Third party on-site testing report.

7. Power Absorber (VAD) and Tuned Mass Damper (TMD)

产品型号VADTMD | -2 | -10 | -500 | -1000 | -5000 | -10000 |

装置质量块质量(kg) | 2 | 10 | 500 | 1000 | 5000 | 10000 |

控制频率(Hz) | 0.5∽50 | |||||

吸振效果(dB) | >3 | |||||

产品质量(kg) | 可定制设计 | |||||

几何尺寸(m) | 可定制设计 | |||||

环境温度(℃) | -30∽100 | |||||

耐腐蚀 | 满足海洋环境使用要求 | |||||

The above parameters are standard and can be customized according to customer requirements.